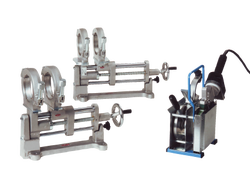

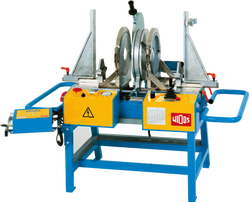

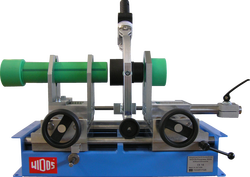

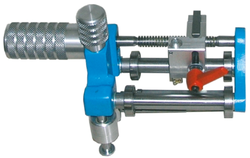

Miniplast 2Welding machine for the heating element butt welding of pipes and fittings out of PE, PP and PVDF from OD 20 up to OD 110.

Also available as extended version for T-piece fabrication and optionally with electrical planer. |

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS mobile version

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

WIDOS

|

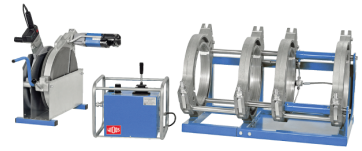

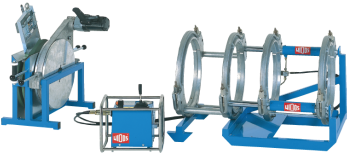

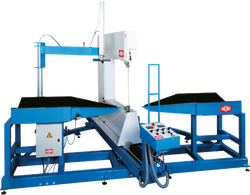

WIDOS 12000 WMManual welding machine for the heating element butt welding of pipes and fittings out of PE and PP from OD 500up to OD 1200. Also appropriate for the fabrication of T-pieces 45°, 60° and 90° and cross-pieces. The welding machines can easily be retrofitted with the SPA weld log recorder and are also available in CNC controlled version.

|

WIDOS 16000 WM/20000 WM/

|

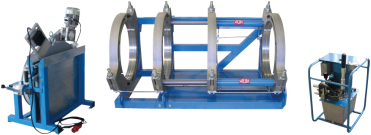

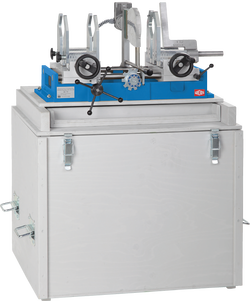

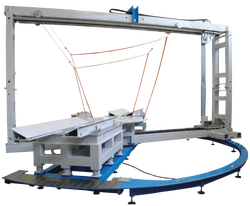

WIDOS Servo driven machinesServo controlled welding machines for the heating element butt welding of pipes and fittings out of PE, PP, PVDF and PVC from OD 90 up to OD 1200 for the economic fabrication of fittings, bends, T- and cross-pieces of the highest quality. The machines are controlled by the WIDOS CNC 3.0 control unit that permits an exact fabrication as well as logging of the weldings.

|

WIDOS electrical socket welding machines

|

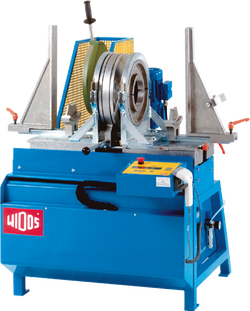

WIDOS PSM 10/PSM 15Manual sheet welding machines for the processing of sheets and boards of all common thermoplastics with a length of max. 1500 mm and a thickness of max. 20 mm for full wall sheets resp. for twin-wall sheets of up to 60 mm.

Optionally, the machine is available with clamping beams for the welding of angles up to 90°. WIDOS PSM 20Manual sheet welding machine for the processing of sheets and boards of all common thermoplastics with a length of max. 2000 mm and a thickness of max. 20 mm for full wall sheets resp. for twin-wall sheets of up to 60 mm.

Optionally, the machine is available with clamping beams for the welding of angles up to 90°. |

WIDOS Motorized manual

|

WIDOS Sawing system 315Sawing system for plastic pipes up to OD 315 in a closed modern steel construction. The saw frame can be bilaterally swivelled by at least 45° resp. 67,5° for the bevelling of pipes. As an option, it is available with a line laser in order to indicate the later cutting course as well as pneumatic pipe clamping and can be retrofitted for radial cuts.

|

WIDOS

|

WIDOS

|

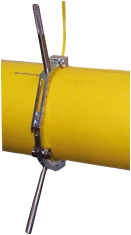

WIDOS RollerstandsRobust and simple rollerstands that are insensitive to dirt for the optimal alignment of the pipes on site and for the reduction of the movement forces.

5 different types of rollerstands with load capacities from 500 kg up to 2000 kg and hydraulic vertical adjustment are available. |